Hygiene Miele Professional

Hygiene measures to prevent the spread of viral infections

To curb the spread of viruses, special hygiene measures are necessary, particularly in sensitive areas. This site contains a wealth of information on the subject of hygiene and on the special services provided by Miele Professional.

Care and nursing homes

Giving protection pride of place: Hygiene measures in care and nursing homes

Residents in care and nursing homes are particularly vulnerable. Not least during the current outbreak of Corona (Covid-19), it is essential to guarantee strict hygiene in daily laundry-care and cleaning routines. Proper and professional reprocessing of laundry, crockery and medical equipment can help curb the spread of the virus and slow down its rate of propagation.

With your Miele Professional machines, you are on the safe side as these products were specifically designed, built and tested to meet the highest of hygiene requirements. By following our instructions, you can also be sure of deactivating and killing potential viruses and bacteria.

Hygiene in the laundry field

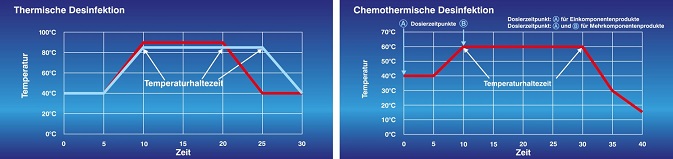

Laundry should always be washed in a thermal or chemo-thermal disinfection process in accordance with the provisions of national bodies and hygiene associations on infectious diseases. Furthermore, staff should wear personal protective gear such as gloves, possibly a plastic apron over their workwear, and a suitable face mask.

PPE and possibly contaminated workwear should always remain on the laundry premises. In order to protect oneself and others, these items should never be taken home for washing in a domestic machine!

Hygiene tips on the use of barrier machines

- In your business, ensure that staff members collect soiled textiles in suitable colour-coded laundry bags, ideally pre-sorted in self-opening bags for further processing in the laundry.

- Load washing machines with the self-opening bags without first removing the contents. Self-opening bags unwrap automatically during the wash process as long as the drawstring has been released.

- Select the correct wash cycle (thermal or chemo-thermal disinfection cycle) for hygienic reprocessing.

- Make sure when manually dispensing detergent that the prescribed quantity is properly measured and that an appropriate temperature for the specific detergent is set.

- Change your protective clothing before relocating to the unclean side of the operation or unloading machines.

- Always wash workwear and protective clothing within the laundry in a hygiene programme and dispose of single-use items in the proper way.

- In laundries without a diaphragm wall or partition, particular care should be paid to separating clean and dirty areas. This approach ensures your own protection and that of any residents who use the premises.

Hygiene tips on using frontloading washing machines

- In your business, ensure that staff members collect soiled textiles in suitable colour-coded laundry bags, ideally pre-sorted in self-opening bags for further processing in the laundry.

- Load washing machines with the self-opening bags without first removing the contents. Self-opening bags unwrap automatically during the wash process as long as the drawstring has been released.

- Select the correct wash cycle (thermal or chemo-thermal disinfection) for hygienic reprocessing.

- Make sure when manually dispensing detergent that the prescribed quantity is properly measured and that an appropriate temperature for the specific detergent is set.

- Disinfect the door and its surroundings (door, door gasket, machine front) and the control panel before removing clean laundry from the machine.

- Never take workwear home for washing. It should always be processed in the laundry in order to protect the wearer and others. Always use a disinfection wash cycle for this purpose.

- Instruct residents on the correct use of Miele Professional machines and instruct them on further hygiene measures such as hand and surface disinfection.

- Delicate garments require washing at low temperatures. Please contact your detergent supplier in order to ensure the correct choice of detergent and/or disinfectant.

Hygiene in dealing with bedpans and urine bottles

Our bedpan washers are designed to safely reprocess bedpans and urine bottles – proven levels of detergency and the relevant disinfection parameters are also effective in the days of the Corona virus. The pre-installed programmes are designed to deactivate viruses and kill bacteria so that they no longer pose a threat.

Our recommendation: Use an alkaline detergent and a thermal disinfection cycle (all Miele bedpan washers can be operated at an A0 value of 600). There is no need for a special-purpose programme to combat the Corona virus!

Hygiene in the kitchen

Crockery washing is covered by recommendations issued by national infection control authorities and hygiene associations: Only use programmes with elevated temperatures (>60°C) to ensure good hygiene and disinfection.

Observe the basic principles of hygiene when unloading a dishwasher (thorough and regular hand hygiene) in order to avoid the risk of recontaminating clean crockery.

Ensure that sufficient detergent is dispensed on all machines. By way of a further safety measure, we recommend the use of a detergent containing chlorine. Detergent can be reordered from the Miele Professional online shop.

Hygiene tips on the use of fresh water and ProfiLine dishwashers

- Use the 'Intensive', 'Hygiene', 'Hygiene Plus' or 'Vario TD' programmes which all achieve a temperature of 60°C or higher.

- On most of the other programmes, the final rinse temperature can be increased to >70°C via the 'Settings' menu.

- Where available, use the optional drying at the end of the cycle to avoid the need for drying items by hand.

- If available, use automatic detergent dispensing and a dispenser module to avoid the selection of a programme with too little or no detergent at all by mistake.

Hygiene tips on using tank dishwashers

- Use Programme 3 for heavy soiling and the additional 'Intensive' option in the majority of cases.

- Wear gloves if it is necessary to polish glassware or crockery.

- Replace the water in the tank several times a day.

- Clean filters regularly.

Healthcare institutions

Protection comes first: Hygiene measures in the healthcare sector

In the day and age of Corona (Covid-19), it is crucial to subscribe to the strictest of reprocessing standards. The health and safety of patients, users and third parties should not be compromised at any time, neither during treatment nor reprocessing. Professional reprocessing can halt and inhibit the spread of the virus.

Thanks to validated processes, machine-based instrument reprocessing ensures high safety margins and reliable results in washing, disinfection and sterilisation. Associated documentation processes record the individual stages of reprocessing in a complete and uninterrupted manner. Good reprocessing practices serve to disrupt chains of infection.

All the programmes on our Miele Professional washer-disinfectors are capable of thermal disinfection. Hence, VarioTD cycles are perfectly sufficient, even in dealing with the Corona virus. Similarly, no changes to programmes are required.

Hospitals and surgeries

On Miele washer-disinfectors, VarioTD programmes with their structure comprising pre-washing, a main wash with process chemicals, and thermal disinfection, are capable of deactivating the Corona virus. These machines allow not only the reprocessing of the usual medical instruments but also anaesthetic tubing and breathing equipment. A specially designed load carrier for anaesthetic equipment allows up to 8 breathing tubes with a length of 1.5 m and intubation material to be washed and disinfected in a single cycle.

High-performance Miele Cube X small sterilisers ensure the subsequent sterilisation of invasive medical products. EcoDry technology facilitates this in the shortest of times, ensuring fast instrument turnaround, even when patient numbers are high.

Further support is offered by Miele's System4Med, with which we can provide you with assistance with the safe and efficient reprocessing of instruments in combatting Corona. This leaves you with more time for your patients and the sense of security which comes from knowing that your instruments are in the best of hands.

Reprocessing single-use protective equipment in the light of current exceptional circumstances

In order to curb the spread of the Corona pandemic, healthcare workers worldwide require huge quantities of medical and personal protective equipment (PPE). However, the required materials are unfortunately not available in sufficient quantities. The items most subject to shortages are face masks (FFP2/FFP3) and half-masks, but also visors and other items of protective equipment are also in short supply. In order to alleviate this shortage of single-use supplies in such a strained situation, some countries are now allowing the reprocessing of equipment – subject of course to strict regulations and by way of a time-limited exemption for the duration of the pandemic.

Reprocessing FFP2/FFP3 masks and half-masks

If protective masks are reprocessed, this should not impair the fit and seal provided by the material nor the proper functioning of the items concerned. The situation is further exacerbated by the fact that the recommendations issued by the various countries are by no means uniform. As a result, it is important to fulfil national requirements which in part vary significantly and are also subject to constant change. For specific information, please contact your local authorities responsible for infection control, health and occupational safety.

The processes discussed and in part tested include the following:

- Reprocessing using dry heat (temperature: 65°C to 70°C, holding time: 30 minutes)

- Reprocessing using moist heat (temperature: 121°C, holding time: 15 minutes)

With Miele, you have chosen a reliable partner. Our service team is not only able to locate the most suitable products from our broad portfolio to meet the specific requirements of your business. Our extensive expertise in the field of application technology also allows us to support medical institutions in their choice of a tailored reprocessing system. Please do not hesitate to contact our colleagues in Sales and Service direct.

Reprocessing of protective goggles and visors

Alongside protective masks, healthcare staff involved in in- and outpatient care also requires protective goggles and visors to avoid exposure to viruses such as COVID-19. In view of the tense supply situation with respect to personal and clinical protective equipment, attention is increasingly turning to the reprocessing of googles and visors.

The protective goggles used in the healthcare system are made from a variety of plastics, including polycarbonates, acrylic glass, polysulphones or polyphenylsulphones. The reprocessing method used should not impair these materials in any way and should be geared to the needs of the various plastics and be in accordance with manufacturers' instructions. Thermally resistant loads can be reprocessed in Miele washer-disinfectors. Typically, reprocessing subdivides into various process stages:

- Pre-wash: 1 - 3 minutes (cold tap water)

- Main wash: 10 minutes at a temperature of 55°C (fully demineralised water) and a dispensing concentration of 0.5% (5 ml per l) using a suitable detergent

- Neutralisation: 1 minute (cold, fully demineralised water), dispensing 0.2% of a suitable neutralising agent

- Interim rinse: 1 minute (cold, fully demineralised water)

- Disinfection: 5 minutes at 55°C (cold, fully demineralised water)

Miele's sales and service staff is able to provide fast and uncomplicated advice on washer-disinfectors and the most suitable load carriers and modules for both new and existing machines.

Reprocessing of hand disinfectant bottles

Alongside protective equipment, 500 ml and 1000 ml hand disinfectant bottles are also in short supply. Increasingly, hospitals, apothecaries and other medical faculties have taken to making their own hand disinfectants. Here, too, the aspect of reprocessing items which are usually intended for single use is growing in significance.

Hygienic reprocessing can be achieved using Miele washer-disinfectors: Laboratory bottles with volumes of 500 ml and 1000 ml can be washed, disinfected and dried using EasyLoad load carriers. The EasyLoad system is available on Miele machines of various sizes. For further information, please contact our colleagues in Sales and Service.

Dental medicine

On Miele thermal disinfectors, the VarioTD dental programme with its structure comprising pre-washing, a main wash with process chemicals, and thermal disinfection, is capable of deactivating the Corona virus.

High-performance Miele Cube X small sterilisers ensure the subsequent sterilisation of invasive medical products. EcoDry technology facilitates this in the shortest of times, ensuring fast instrument turnaround, even when patient numbers are high.

Information on further support and assistance is contained in our dental story brochure revolving around Miele's System4Dent and how we can support you with the safe and efficient reprocessing of dental instruments.

Bedpans

Great caution in the age of the Corona virus must be exercised when using potentially contaminated bedpans and urine bottles. According to the current state of the art, reprocessing with proven levels of cleaning performance followed by thermal disinfection is also effective in dealing with the Corona virus.

This virus is deactivated and rendered harmless by the pre-installed programme parameters. The use of an alkaline detergent (for example ProCare Med 10 BPA) followed by thermal disinfection with an A0 value of at least 600 is recommended. All Miele bedpan washers can be operated at this A0 value.

Miele bedpan washers protect not only patients but also those who have to handle them. Thanks to the option of footswitch-operated door opening and closure, there is no need for direct contact with the door, allowing for contact-free loading and unloading. The programme starts automatically on closing the door. In addition to the above, the A0 value can be adjusted to the needs of hospitals to a maximum value of 3000.

Facility management

Giving pride of place to protection: Hygiene measures for contract cleaners

In an age dominated by the Corona virus, the highest levels of hygiene and disinfection are of the essence – no matter whether in office blocks, hospitals, food stores or public buildings. In all these places, contaminated hands can transfer pathogens to noses, eyes and the mucous membranes in the mouth, causing infections. Neuralgic points of contact include handles on doors, windows and cupboards, light switches, banister rails and the controls in elevators. In such cases, wipe disinfection ensures a higher level of protection. Similarly, the professional reprocessing of cleaning textiles helps curb and slow down the spread of viral diseases.

Your Miele Professional machines are able to rise to this challenge as all Mopstar units have thermal and chemo-thermal disinfection programs and ensure the safe reprocessing of your cleaning textiles. In addition to this, we will provide you with tips and tricks on how to deactivate existing viruses and kill bacteria.

Safe disinfection of cleaning textiles

Always wash cleaning textiles such as mops and cleaning cloths in a thermal or chemo-thermal disinfecting wash. Our Miele Professional MopStar models comply with the strict provisions issued by European infection control authorities and hygiene associations. In addition to this, we offer further safety devices and mechanisms which monitor automatic dispensing and ensure that temperatures are precisely maintained. Hence, your Miele Professional MopStar machines guarantee excellent margins of safety in the hygienic reprocessing of cleaning textiles.

Impregnation of cleaning textiles

All MopStar models feature the 'ready-to-use' function in which washed textiles are impregnated with detergent and/or disinfectant prior to re-use. Reuseable cleaning textiles are prepared for the next cleaning job in a specially designed programme cycle. This saves cleaning staff valuable time in their work. Always observe hygiene rules on the use of disinfectant as well as restrictions on storage times.

Hygiene tips on dealing with cleaning textiles

Collect used cleaning cloths and mops in appropriate containers. Avoid the possible cross-contamination of cleaning textiles already washed.

Separate clean from unclean areas in a laundry, at least administratively if not physically.

- Avoid overloading with cleaning textiles when loading machines.

- Select the correct wash cycle (thermal or chemo-thermal disinfection) for hygienic reprocessing.

- Make sure when manually dispensing detergent that the prescribed quantity is properly measured and that an appropriate temperature for the specific detergent is set.

- Carefully select the intended programmes and parameters for reprocessing cleaning textiles with subsequent conditioning for re-use.

- Disinfect the door and its surroundings (door, door gasket, machine front) and the control panel before removing clean laundry from front-loading machines.

- Sort cleaning textiles after removal into clean and disinfected containers only.

- If washing is followed by drying, ensure that items are fully dried. Always remove textiles immediately at the end of the drying process.

- Never take workwear home for washing. It should always be processed in the laundry in order to protect the wearer and others. Always use a disinfection wash cycle for this purpose.

- Always wear personal protective equipment such as protective gloves and plastic aprons in the unclean area in accordance with health and safety guidelines and hygiene regulations for your own personal safety.

Reprocessing ofworkwear andprotective clothing

Giving protection pride of place: The hygienic reprocessing of workwear and protective clothing.

Whether surgery, hospital or ambulance service: In order to protect oneself and others, it is particularly important to subscribe to hygiene rules. During the current outbreak of Covid-19, more than at any other time, the proper use of protective clothing is vital. This applies to healthcare workers such as those in dental and medical surgeries, consultants in hospitals as well as paramedics and members of emergency rescue services.

Equally so, it is important that workwear and protective apparel is reprocessed in a disinfecting wash. The proper reprocessing of textiles and personal protective equipment helps in deactivating viruses such as Covid-19 and in slowing down their spread. With Miele, you have chosen a reliable partner. Miele Professional machines comply with the strict provisions issued by national infection control authorities and hygiene associations. With their thermal and chemo-thermal disinfection programmes, they always produce reliable and reproducible results on workwear and protective clothing. Our tips and tricks are aimed at ensuring that any potential viruses are rendered inactive and bacteria killed.

[The recommendations given refer exclusively to reusable workwear and protective clothing and not to single-use products.]

Hygiene measures aimed at GPs and specialists with their own practice

Potentially contaminated workwear and protective apparel must remain within the surgery throughout. In order to protect oneself and others and ensure proper reprocessing, staff should on no account take laundry home for washing. This prevents cross-contamination through contact with private laundry.

When loading and unloading machines with workwear and protective clothing, staff should take precautions such as wearing protective gloves and a plastic apron over their own workwear.

Hygiene tips on using frontloading washing machines

- Separate dirty areas in the laundry from clean zones, at least administratively if not physically, in order to avoid any recontamination of clean textiles.

- Select the correct wash cycle (thermal or chemo-thermal disinfection) for hygienic reprocessing.

- Make sure when manually dispensing detergent that the prescribed quantity is properly measured and that an appropriate temperature for the specific detergent is set.

- Disinfect the door and its surroundings (door, door gasket, machine front) and the control panel before removing clean laundry from the machine.

Hygiene measures in hospitals

PPE and possibly contaminated workwear should always remain on the laundry premises. In order to protect oneself and others and to prevent cross-contamination, these items should never be taken home for washing in a domestic machine!

In the interests of increased hygiene, personnel should under current circumstances wear protective equipment such as gloves, an apron over their workwear and a suitable face mask.

Hygiene tips on the use of barrier machines

- In your business, ensure that staff members collect soiled textiles in suitable colour-coded laundry bags, ideally pre-sorted in self-opening bags for further processing in the laundry.

- Load washing machines with the self-opening bags without first removing the contents. Self-opening bags unwrap automatically during the wash process as long as the drawstring has been released.

- Select the correct wash cycle (thermal or chemo-thermal disinfection cycle) for hygienic reprocessing.

- Make sure when manually dispensing detergent that the prescribed quantity is properly measured and that an appropriate temperature for the specific detergent is set.

- Change your protective clothing before relocating to the unclean side of the operation or unloading machines.

- Always wash workwear and protective clothing within the laundry in a hygiene programme and dispose of single-use items in the proper way.

- In laundries without a diaphragm wall or partition, particular care should be paid to separating clean and dirty areas. This approach ensures your own protection and that of any residents who use the premises.

Hygiene tips on using frontloading washing machines

- In your business, ensure that staff members collect soiled textiles in suitable colour-coded laundry bags, ideally pre-sorted in self-opening bags for further processing in the laundry.

- Load washing machines with the self-opening bags without first removing the contents. Self-opening bags unwrap automatically during the wash process as long as the drawstring has been released.

- Select the correct wash cycle (thermal or chemo-thermal disinfection) for hygienic reprocessing.

- Make sure when manually dispensing detergent that the prescribed quantity is properly measured and that an appropriate temperature for the specific detergent is set.

- Disinfect the door and its surroundings (door, door gasket, machine front) and the control panel before removing clean laundry from the machine.

- Never take workwear home for washing. It should always be processed in the laundry in order to protect the wearer and others. Always use a disinfection wash cycle for this purpose.

- Instruct residents on the correct use of Miele Professional machines and familiarise them with further hygiene measures such as hand and surface disinfection.

- Delicate garments require washing at low temperatures. Please contact your detergent supplier in order to ensure the correct choice of detergent and/or disinfectant.

Makeshift Masks / ‘Community Masks’

In the current COVID-19 pandemic, there is a shortage of surgical and respiratory protection masks (FFP masks). As a result, many companies are using non-medical makeshift masks from cloth, also known as community masks.

Although these makeshift masks do not meet the standard medical requirements, they can provide a physiological barrier due to their barrier function. In this way, they reduce the distribution and spread of larger droplets (e.g. through coughing or sneezing) and prevent contact infections (e.g. by touching the oral and nasal mucosa with contaminated fingers).

Preparation of ‘community masks’ in a commercial environment

According to the national authorities for occupational health and safety, the use of ‘community masks’ for employees who come in contact with people is conceivable. In order to ensure masks can be reused after being worn once, preparation under the following parameters is recommended:

- Follow the reprocessing instructions of the mask manufacturer.

- In addition to SARS-CoV-2, other microorganisms of the oral flora (such as Staphylococcus aureus and Streptococcus pyogenes) must also be sufficiently reduced. Therefore, choose washing methods with bactericidal, yeasticidal and virucidal properties.

- After removal, seal the mask in an airtight bag (or similar) or wash immediately. It should be kept sealed for as short a time as possible, in particular to avoid mould growth. A disinfecting washing process in compliance with regulatory requirements can be safely carried out in commercial washing machines.

- A large number of Miele commercial washing machines have both thermal and chemo-thermal disinfecting washing programmes. While commercially available detergents can be used when washing textiles for thermal disinfection, only listed products in accordance with the specifications are to be used for chemo-thermal disinfection.

- Moisture and storage time favour the multiplication of germs. Therefore, make sure that the masks are completely dry after the washing process.

- Check the functionality of the masks after reprocessing: Parts with a visibly changed size, holes or torn bands should not be put into circulation again.

Paramedics, emergency and rescue services

The correct reprocessing of workwear and PPE is elementary to the safety of emergency and rescue workers. With products from Miele Professional, apparel can be washed and disinfected and personal protective equipment such as breathing masks and air regulators can be washed hygienically.

Depending on the area of responsibilities and the layout of the site, washing machines and dishwashers can be combined to create a holistic system – even comprising machines of differing sizes.

Hygienically prepare respiratory protection equipment for fire departments

The safety and health of rescue workers are top priority. In times of the coronavirus pandemic, reprocessable respiratory protective equipment is of particular importance. This means that the highest processing standards must be guaranteed for hygienic cleaning. After all, professional reprocessing can break the infection chain.

Coordinated processes ensure a high degree of safety in the mechanical reprocessing of respiratory masks and regulators - both for cleaning and disinfection. With the Miele PG 8063 OK Safety dishwasher, respirators and regulators can be safely and hygienically reprocessed. Most respiratory protection materials are sensitive to heat (thermolability). We therefore recommend chemo-thermal disinfection during reprocessing, for example with the disinfectant and cleaning agent Sekumatic FDR * from Ecolab. With this product, all programmes of the PG 8063 OK Safety meet the parameters to be observed for chemo-thermal disinfection. It is not necessary to adapt the programmes. In general, the basic reprocessing recommendations of the equipment manufacturers must be observed.

* Use biocides safely. Please always pay attention to labelling and product information before use.

Systematic solutions for fire brigades and emergency services

Miele has designed special-purpose machines to meet the specific demands of emergency and rescue services:

- Washing machines for personal protective equipment and breathing masks

- Barrier washing machines for maximum hygiene

- Dryers

- Washers for breathing masks and air regulators

- Washer-disinfectors for breathing masks and anaesthetic equipment