Systematic solutions for contract cleaners

High demands are not only placed by contract cleaners on thorough cleaning and safe hygiene but also on an economic and cost-efficient process – that is why Miele Professional developed MopStar washing machines to rise to the challenges of modern facility management.

ContactStep 1

Optimum results at the flick of a wrist

Simple and safe operation

Washing machines and tumble dryers from Miele Professional allow intuitive and error-free operation and are conducive to smooth and glitch-free working conditions. Programmes and further functions are selected using a large rotary selector or function buttons; all messages are portrayed in a clear and concise display in the language of choice.

MopStar washing machines and tumble dryers offer numerous special-purpose programmes for a broad range of textiles, e.g. for the disinfection and conditioning of mops and cleaning cloths as well as for pads, curtains and floor mats. An additional margin of hygiene is provided by a programme which thoroughly sanitises the machine. Even workwear can be conveniently washed on site.

Benefits that pay off on a daily basis

• Numerous special-purpose programmes for contract cleaners, e.g. mops, cleaning cloths, pads, curtains, floor mats, etc.

• Comprehensive hygiene thanks to programme for machine sanitisation

• Efficient work planning with delay-start feature

• Intuitive operation with text display and ergonomically designed controls

• Excellent operational safety thanks to individually selectable user interface language (29 languages available)

Step 2

First-class cleanliness and protection of fabrics

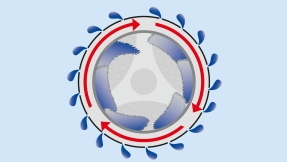

Miele honeycomb drum

Mops are given kid-glove treatment in Miele's honeycomb drum, ensuring gentle protection and preserving values. Precisely cut perforations in the drum rear panel feature carefully rounded edges. Laddering, which puts great strain on textiles, is reduced to a bare minimum compared with a conventional drum – even at high spin speeds.

Copious tests and field trials conducted by the independent wfk Cleaning Technology Institute confirm the high cleaning performance of the Miele honeycomb drum. Compared with a conventional drum with large perforations, the Miele honeycomb drum showed no drawbacks in terms of the removal of soil. Thermal disinfection in Miele washing machines with a honeycomb drum was also evaluated in accordance with Robert Koch Institute (RKI) guidelines, and a sufficient deactivation of pathogens and safe hygiene has been confirmed by the wfk institute.

Step 3

Perfectly aligned technology

Cantilever heater elements

The heater elements in MopStar washing machines from Miele Professional are designed in such a way as to allow water to pass freely. Even fibrous particles such as hairs and fibres are removed by the passage of water before they even have a chance to cling to the heater elements. This also ensures the fast transfer of heat to the wash water.

Step 4

READY TO USE – Cleaning, reprocessing and conditioning in a single cycle

Things couldn't be simpler or more convenient: With the processes developed by Miele Professional for the automatic reprocessing of mops and cleaning cloths, washing and conditioning with detergent or disinfectant takes place in a single cycle. The residual moisture value is easy to set via the programme controls.

Automatic immersion ensures precise and uniform dispensing and does away with the need to manually mix detergent and disinfectant solutions. The need to wring out items by hand has now been banished — mops and cleaning cloths are ready for re-use on removal from the machine. The ready-to-use approach results in significant savings, not only with respect to water and chemicals but also to valuable working time. Cleaning performance also increases as residual moisture levels can be set precisely to suit individual needs.

Step 5

System efficiency

Cost-efficiency in contract cleaning is not only a question of selecting the right machine, it is also a question of accessories. Alongside powerful washing machines, Miele Professionals offer a perfectly matching portfolio of features and accessories to meet commercial needs, including plinths with and without a fluff filter box, and a communication box to network with external systems. This allows you to get on with your work ergonomically, even when under duress.

Product overview

MOPSTAR washing machines

PROFITRONIC M washing machines

Little Giants and SlimLine dryers

PROFITRONIC B Plus and PROFITRONIC M dryers

Load capacities

| Model range | LITTLE GIANTS | LITTLE GIANTS |

OCTO-PLUS |

OCTO-PLUS | BENCH-MARK | BENCH-MARK | PROFI-TRONIC | PROFI-TRONIC | PROFI-TRONIC |

|---|---|---|---|---|---|---|---|---|---|

| Designation |

PWM 506 |

PMW 508 Mop Star 80 |

PW 5084 Mop Star 80 |

PW 5104 Mop Star 100 |

PW 413 Mop Star 130 |

PW 418 Mop Star 180 |

PW 6163 | PW 6241 / PW 6243 | PW 6321 / PW6323 |

| Controls | M Select Mop | M Select Mop | Profiline B Symbole | Profiline B Symbole | Profitronic D | Profitronic D | Profitronic M | Profitronic M | Profitronic M |

| Drum volume [l] | 57 | 73 | 80 | 100 | 130 | 180 | 160 | 240 | 320 |

| Load capacity [kg] | 6 | 8 | 8 | 10 | 13 | 18 | 84 | 24 | 32 |

| Load capacity / Items | |||||||||

| Cotton mops 190 g / 40 cm | 31 | 42 | 42 | 53 | 68 | 95 | 84 | 126 | 168 |

| Cotton mops 220 g / 50 cm | 27 | 36 | 36 | 45 | 59 | 82 | 73 | 109 | 145 |

| Cotton mops 360 g / 80 cm | 16 | 22 | 22 | 28 | 36 | 50 | 44 | 67 | 89 |

| Microfibre mops 120 cm / 40 g | 50 | 66 | 66 | 80 | 108 | 150 | 130 | 200 | 260 |

| Microfibre mops 170 cm / 50 g | 35 | 47 | 47 | 55 | 76 | 106 | 90 | 146 | 180 |

| Microfibre mops 250 cm / 75 g | 24 | 32 | 32 | 40 | 52 | 72 | 64 | 96 | 128 |

| MicroClean cloths 16 g | 188 | 250 | 250 | 313 | 313 | 565 | 500 | 750 | 1000 |

| Quickstar 22 g | 136 | 182 | 182 | 227 | 227 | 410 | 364 | 545 | 727 |